SUCCESS CASE:

HGK CTS TERMINAL

SHIP-TO-SHORE CONTAINER TRACEABILITY

About HGK CTS Terminal

HGK Logistics and Intermodal is a leader in container logistics along the Rhine, with four of its own terminals connected tri-modally from Duisburg to Cologne.

CTS Container Terminal GmbH is the largest tri-modal container terminal and currently the largest transhipment facility of the intermodal group. Located in the port of Cologne-Niehl, CTS is a central hub in one of Germany’s most important economic and industrial regions.

The Challenge: OCR at Gantry Cranes

CTS faced the challenge of ensuring the traceability of containers loaded and unloaded by the cranes, including verification of the presence of seals on the containers. In addition, obtaining proof of condition (images) of any related incidents was an important component.

Handling approximately 200,000 containers per year with 3 gantry cranes, the risk of handling errors was a concern. Despite the existence of automation solutions, a satisfactory return on investment (ROI) of the existing solutions was not assessed.

The Solution: AllRead ARSⒸCranes

The project originated in HGK’s innovation hub, “Innovation Harbour Cologne“. AllRead was selected to solve the challenge by implementing an end-to-end solution at the CTS terminal.

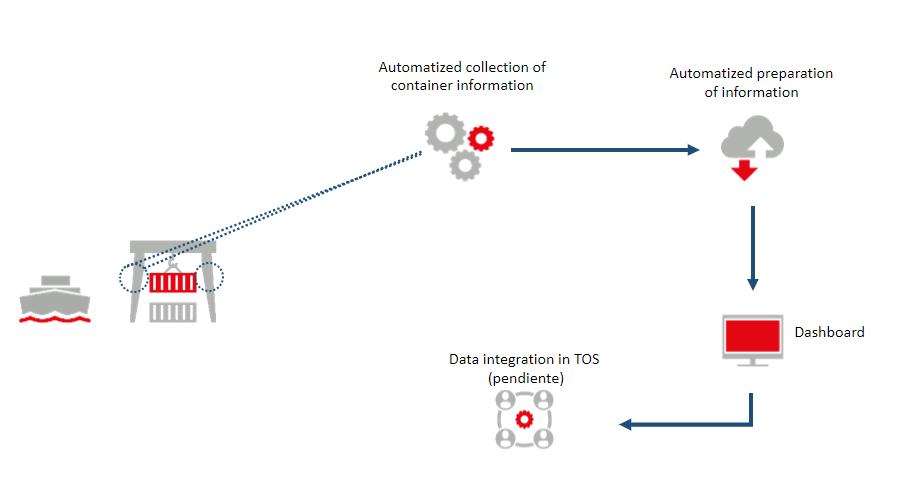

The edge server was mounted on one of the cranes, where the videos sent by the IP cameras were processed to send the extracted data to a Cloud platform via 4G in real time. From there it was sent to the TOS to be integrated and consolidated with the loading and unloading lists. The cameras were strategically positioned on the cranes to detect any container movement, both day and night.

The captured data and associated images were then available on the AllRead visual interface.

The Result: Performance Improvement

Succeful data detection

Container Reading per month

Only 2 cameras

The implementation of AllRead’s software generated remarkable results for HGK CTS Terminal. It now registers approximately 750 containers per month, providing readings throughout the day and night. A confidence level in correctly detected container data of over 95% is achieved, with continuous improvement. The group plans to deploy the successful solution at CTS at several of its terminals, due to the results achieved:

- Cost reduction through automated data processing.

- Increased customer satisfaction due to the avoidance of absenteeism.

- Increased volume of transits due to higher throughput.

In addition, the solution proved its effectiveness at an early stage of the project, identifying several possible lost containers and demonstrating its potential to prevent losses and improve operational safety. The success of the solution has laid the foundation for future HGK applications, in cranes and on rail tracks.