Every year, 10,000 million tons of cargo are moved by sea. This causes about 3% of the world’s greenhouse gases, as well as 13% of nitrogen oxide (NOx) emissions and 12% of sulfur oxide (SOx) emissions. [1]

The International Maritime Organization (IMO), the UN body that regulates the shipping industry, has set a goal of halving the sector’s carbon emissions by 2050 compared to 2008 levels, with the goal of eliminating them completely. [2]

Therefore, Ports and Terminal Operators play a fundamental role in the decarbonization of the economy. There are many pathways that can lead to the decarbonization of Ports and their surroundings. The challenge? Harmonizing the bustling activity of freight logistics with the pressing need to reduce the environmental footprint. This balance is crucial for Ports that aspire to make a positive contribution to the planet and society.

Gradually, Ports and Terminals began to take measures to reduce their environmental impact. For example, the Port Authority of Valencia has managed to reduce the carbon footprint of the facilities by 17% in six years, while the volume of tons handled has increased by 14%. [3]

There are several technologies and processes that contribute to the reduction of the carbon footprint in the Port sector. We list some of them below. Subsequently, we will focus in detail on the impact that the implementation of OCR systems can have.

1. Recommended pathways for Port decarbonization

The European Institute of Innovation and Technology (EIT) has published a practical guide for the decarbonisation of Ports, focusing on seven recommended pathways. [4]

1. Transitioning ships to clean energy.

With global transport responsible for approximately 24% of all CO2 emissions and shipping accounts for 10% of total transport emissions, it is imperative for Ports to help facilitate ships’ transition to clean energy. Electrification and the use of green hydrogen and bioenergy will be key to fostering the transition, and ports will play a key role in providing refueling and refueling stations for newly propelled vessels. Hybridization of transport vessels can also play an important role in reducing emissions in the transition phase. Hybrid vessels have a conventional diesel engine and an electric motor, which when in use, does not consume diesel and therefore no greenhouse gases are released.

2. Decarbonizing logistics in Ports.

Ports are responsible for a variety of direct and indirect carbon emissions within logistics activities, such as diesel-powered coastal infrastructure (to move containers, cranes, etc.), the consumption of non-renewable electricity used to power buildings, lighting, and various machinery, and all indirect emissions from vehicles transiting ports to deliver and load cargo. All these activities present opportunities for decarbonisation, with smart technologies to optimise container handling and turnaround time, or using a combination of electrification (with renewable energy sources) and greater energy efficiency.

3. Decarbonization of industries in Ports.

The type of industries that harbors contain varies depending on the size and infrastructure of the port, but can include shipbuilding, chemicals, food, construction, petroleum, electric power, steel, fish processing, and automotive industries. The carbon tax, specifically for energy-intensive industries such as steel and chemicals, represents a huge incentive for these industries to pursue lower-emission production methods. Pathways for the decarbonization of industries within ports include the use of renewable heat for the operation of industrial processes, the improvement of energy efficiency within existing processes, the electrification of processes, the use of green hydrogen as a feedstock, the employment of circular production models and the use of waste heat.

4. Decarbonization of energy production in ports.

Ports can become major producers and providers of clean energy and heat solutions for the economy. They already have strong grids and connect large consumers of electricity, and since they provide ideal landing points for the planned capacity of offshore wind, they will be vital to the development of this renewable energy source. Ports also have great potential to host the development of large-scale electricity storage, which will be needed to balance fluctions in supply and demand, and to facilitate the transdecarbonization of hydrogen.

5. Decarbonizing Port maintenance.

Maintenance activities and construction works in Ports offer new opportunities for decarbonisation, using renewables, off-grid storage to power tools, and switching from diesel machinery to electrified options. Dredging companies will have to modify their vessels and switch to carbon-neutral fuels, electrify or hybridize their vessels and equipment.

6. Clean energy for buildings.

Company buildings within ports will also play a role in reducing emissions by transitioning to cleaner energy sources and are expected to harness renewable energy wherever possible. Smart software solutions will help enable more efficient use of energy, and digital heat management will also be incorporated into the solutions.

7. Monitor, measure, and disclose emissions and other impacts

A final activity that unites all these clusters and decarbonization efforts is sustainability reporting, to measure, manage, and communicate efforts to reduce emissions. In the EU, it is currently mandatory for all companies with more than 500 employees to report on their non-financial impacts (which include emissions) and an increasing number of smaller companies are also voluntarily reporting their impacts. Big data is involved in measuring and managing an organization’s sustainability impacts and some interesting new technologies have been developed to manage such amounts of data.

2. OCR to decarbonize logistics in Ports

In second place in the EIT’s catalogue of solutions is “Decarbonising logistics in ports”. This refers to all emissions from diesel-powered or non-renewable electricity vehicles and machinery used by the ports themselves to load and move cargo, as well as all vehicles (in particular trucks) entering and leaving Ports to deliver or pick up cargo. The implementation of Port OCR improves the traceability of vehicles and goods, and optimizes processes. Consequently, by increasing port efficiency, OCR contributes to reduce CO2.

2.1 Reducing waiting times.

Despite all the advantages of intermodality, the truck transport of containers faces queues and retentions that are generated in the Terminals on a daily basis. In peak time, according to Fenatport (Spanish Federation of Autonomous Port Transporters), truck waiting times can last up to three hours. [8]

Relying on various documented measurements in terminals around the world, and for the sake of making an estimate, let’s consider 20 minutes average waiting times for trucks at Terminal access controls. The time the truck remains waiting represents kilos of CO2. More precisely, an idling truck consumes 3,5 liters of fuel per hour. With 2,67kg of CO2 per liter of fuel (diesel) burned, we are talking about 9,34kg of CO2 emitted every hour, to be multiplied by the daily transits, every day, in every Port access.

OCR access automation ensures a faster flow of traffic, streamlined verification processes, and automated accesses that allow trucks to enter and exit quickly and safely. Therefore, the spread of automatic road access control systems means a reduction in truck waiting times and the corresponding CO2 emissions. If we extrapolate a deployment on the scale of Spain (based on the current volumes of TEUs), with for instance 5 minutes of shorter waiting time per container, this will allow a reduction of 11,545 tons of CO2 per year.

2.2 Optimizing vehicle movements in the Yard.

Vehicles used in Ports and Terminals, in particular trucks, forklifts, reachstackers, industrial tractors (such as MAFIs), perform countless movements in the yard, to move, load or stack containers. The optimization of these journeys represents an opportunity for Port actors to improve performance, extend the life of the machinery and reduce fossil fuel consumption. OCR helps to organize inbound flows into the port, and thus movements within the Port. For example, the automatic detection with OCR of containers entering by rail, and the delivery of their precise positions within the wagons, speeds up the loading and unloading process, optimizes waiting times and the movements of potentially polluting vehicles.

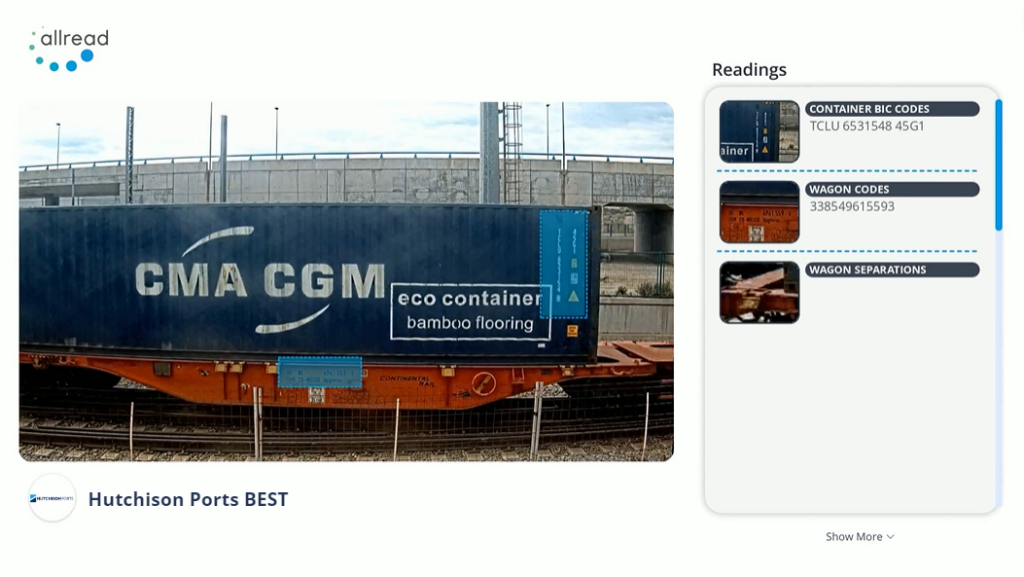

In Hutchison BEST, the implementation of AllRead made notable improvements by quickly processing video streams and providing complete data on the composition of the trains. From 40 minutes of data capture processing time to 10 minutes of data pass-through, BEST achieved an efficiency improvement of 80%, which allowed BEST to manage unloading more effectively both day and night. [Read more about this case.]

Optimizing vehicle movements also has an immediate impact on their lifespan. Take forklift tires for instance: their lifespan depends on their hours of operation, from 5.000 to 10.000 hours for solid tires for instance. The more the operators optimize the movements, the more they maximize the lifespan of the tires. By extending the lifespan of hardware, one increases the “return” on the carbon footprint associated with the manufacturing of these tires.

2.3 Implementing OCR for monitoring and measuring emissions.

On the other hand, in reference to the practical guide for the decarbonization of ports published by the EIT, more specifically about “Monitoring, measuring and disclosing emissions and other impacts, the automatic recognition of the type of vehicles circulating through gate controls makes it possible to measure not only the number of transits but also the environmental impact.

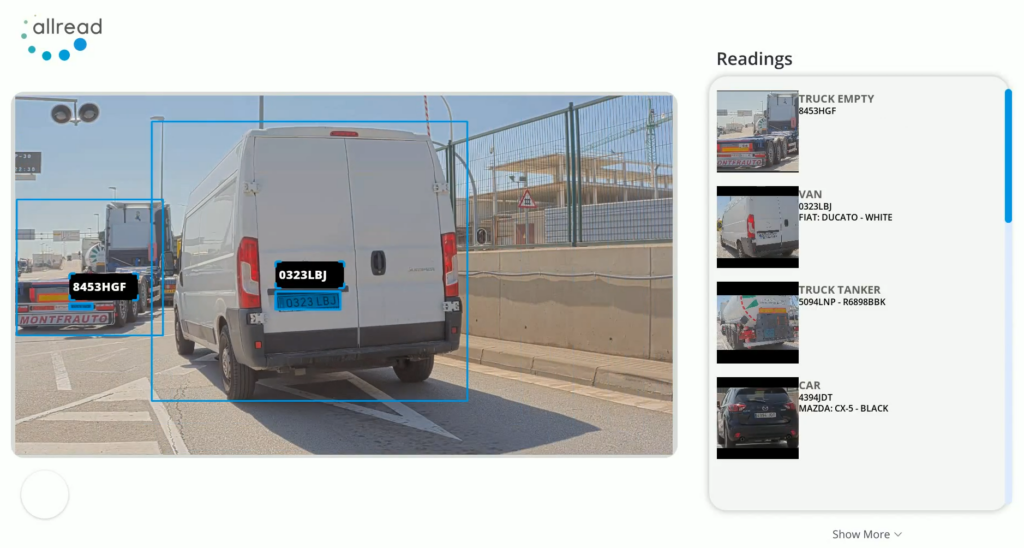

AllRead offers a solution for the automatic identification of vehicles, which makes it possible to distinguish between different types of means of transport (trucks, vans, cars, motorcycles, buses, etc.), as well as the recognition of the brand and model of the vehicle in order to differentiate between electric, hybrid, petrol vehicles, and types of vehicles with different environmental load levels (4×4 vs city car for example). These recognition systems allow Terminal Operators to have data to measure how many vehicles of each type have been circulating through their facilities throughout the day and estimate the impact on CO2.

For instance, according to the European Environment Agency who calculated the average CO2 emissions of pools of car manufacturers, Volkswagen is at 120 grams of carbon dioxide per kilometer (gCO2/km), whereas KIA is around 100 grams [9].

2.4 Less Hardware, Less Associated Material Carbon Footprint

By using the latest technological advancements in artificial neural networks for its OCR and automatic recognition solutions, AllRead’s system does not require the usual hardware infrastructures. Standard installations of OCR gates usually consist of a galvanized steel portal, between 4 and 8 cameras, LED lighting panels, infrared light sources, inductive trigger sensors, laser measurement sensors, etc. AllRead only requires a couple of IP cameras, light spots installed on poles or any other available support (wall, lamppost…), connected by network to a central server.

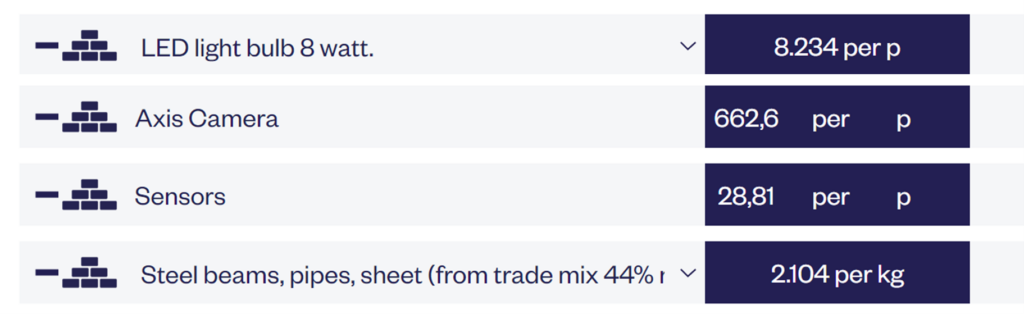

Thus, AllRead not only reduces acquisition and maintenance costs, but also the carbon footprint associated with the manufacturing of the material. Here are some examples of hardware elements spared by an AllRead installation versus traditional OCR gates. Each camera represents 662,6 kilo CO2 equivalent. Sparing 4 cameras in an installation would represent 2.650,4 kCO2 saved. AllRead works without sensors: each Sensor represents 28,81 kilo CO2 equivalent saved.

2.5 OCR to promote the modal shift?

Road transport now accounts for 80% of total freight transport in the European Union. This is followed by rail transport with 5%, and river transport with 2%. [5]

In recent years, the European Commission has sought to address the shortcomings of transport on European territory. Already in 2018, the “multimodal year” brought together relevant initiatives and events, including the “European Single Window” for shipping, which focuses on solutions to move the shipping sector towards a more efficient and sustainable operation through the digitalization of its supply chain. To make this transition possible, the Commission is focusing heavily on promoting rail transport. According to the report by the Observatory of Transport and Logistics in Spain, in the field of digital technologies, although progress has been made, there are still challenges in terms of the digitalization of passenger transport services and freight transport and logistics [6]

Despite this trend and the great willingness of governments to promote this change, few ports in the world have an automatic traceability process for goods entering their facilities by rail. In Spain, for example, until AllRead implemented it at Hutchison BEST, and in the Port Authorities of Bilbao, Algeciras and Valencia, not any Port had Rail OCR, relying on manual and repetitive tasks to carry out the processes of loading, unloading, and tracking cargo arriving and leaving by train.

According to the European Commission, rail freight services suffer from low quality and reliability. This is due to a lack of coordination in the provision of cross-border capacity, traffic management and planning of infrastructure works. Long-term structural changes need to be made to improve the quality of the operating conditions. The right means include investment in better infrastructure, staff skills, digitalization and integration into the logistics chain.

In this line of thought, an interesting environmental effect of AllRead’s solution is its role in facilitating the modal shift from road to rail transport, by improving traceability solutions for assets transported by rail. The disparity in emissions between road and rail transport is remarkable. Currently, according to statistics for 2019, the emissions for truck transport are 111g CO2 per km and for goods trains 17g CO2 per km. This means that more than 6 times as much CO2 is produced for every kilometer that goods are transported by road [7]. AllRead is proud to promote this crucial change for the reduction of CO2 emissions.

Conclusion

The path to sustainable Port ecosystems is complex and requires the integration of a multitude of innovative solutions, strategic planning and a commitment to environmental stewardship. AllRead contributes to this movement, offering powerful tools that enable ports to meet both demands of efficiency and environmental responsibility. Looking ahead, the role of technology in shaping sustainable Port operations cannot be overemphasized.

[2] https://impact.economist.com/ocean/ocean-and-climate/how-the-shipping-sector-is-decarbonising

[3] https://www.valenciaport.com/federico-torres-la-reduccion-de-emisiones-de-co2-es-prioritaria-en-la-estrategia-empresarial-de-la-autoridad-portuaria-de-valencia/

[5] https://www.nytimes.com/2024/03/26/business/france-seine-carbon-emissions.html

[7] https://www.sustamize.com/blog/sustainable-freight-transport

[9] https://www.eea.europa.eu/en/analysis/indicators/co2-performance-of-new-passenger